Best Practices for Building and Maintaining Strong Metal Structures

Key Takeaways

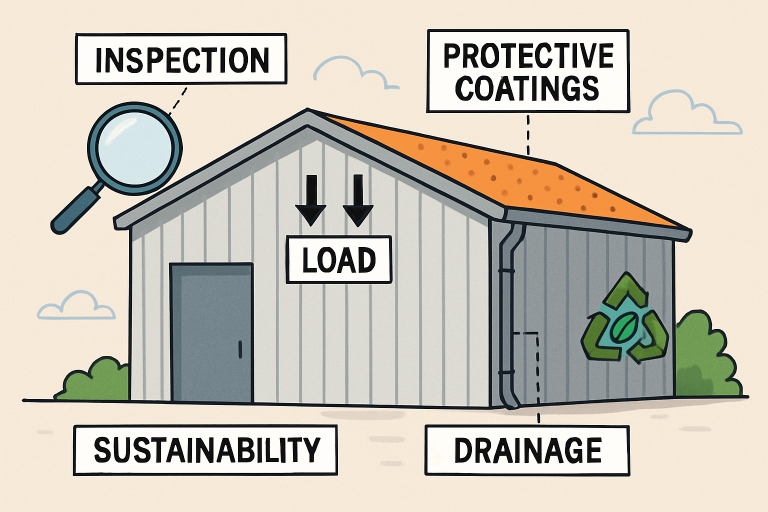

- Regular inspections and maintenance are crucial for the longevity of metal structures.

- Proper material selection and protective coatings can significantly enhance durability.

- Effective load management and drainage systems prevent structural issues.

- Incorporating sustainability practices benefits both the environment and the structure’s lifespan.

Metal structures are trusted for their strength, versatility, and durability, making them the backbone of countless commercial, industrial, and residential projects worldwide. While steel offers substantial benefits in terms of lifespan and performance, its enduring strength depends on how well it’s constructed and maintained. Whether you’re a facility owner, property manager, or working with a steel building manufacturer, understanding the foundational best practices for building and upkeep is vital to ensuring your structure withstands the test of time.

The reliability and cost-effectiveness of a metal structure stem from a combination of advanced engineering, high-quality material selection, and ongoing, proactive maintenance. Focusing only on initial construction without regard for maintenance often leads to early deterioration. Conversely, incorporating long-term strategies from the outset amplifies both safety and return on investment.

With steel construction accounting for a significant share of modern infrastructure, there’s a growing emphasis on using robust approaches at every stage—from design and assembly to daily upkeep. Staying ahead of common issues such as corrosion, water intrusion, and overloading not only safeguards your building but also minimizes repair costs and downtime. This comprehensive guide explores best practices for enhancing the structural integrity and extending the lifespan of your metal investments.

For a detailed industry perspective on maintaining steel buildings and best practices, you may find further insights from RoofersCoffeeShop’s strategies for maintaining metal buildings.

Regular Inspections: The First Line of Defense

Periodic inspections remain the cornerstone of metal building maintenance. Early detection of minor issues, such as cracks, rust spots, or undue wear, can prevent more severe complications, including widespread corrosion or structural fatigue. Conduct inspections at least twice a year and always after extreme weather events such as storms, heavy snowfall, or high winds. Early identification of compromised areas enables timely and less costly repairs, preventing more extensive damage that could compromise safety and functionality.

Regular documentation of inspection findings also helps establish historical baselines, making it easier to track emerging trends or chronic vulnerabilities over time. Experts recommend involving qualified professionals trained to recognize even subtle hints of damage, especially in hard-to-spot structural connections or load-bearing points.

Material Selection: Choosing the Right Steel

The choice of steel used can make or break the structure’s resilience and ease of upkeep. Weathering steels such as ASTM A588 or ASTM A242 have become industry standards for outdoor or industrial settings due to their advanced alloy composition. These steels naturally form a stable surface layer of rust, which actively guards against deeper corrosion without requiring frequent recoating, making them ideal for challenging environments. In applications that demand the highest levels of cleanliness or chemical resistance—such as food processing or medical facilities—stainless steel may be preferable.

It’s also essential to match the grade, thickness, and coatings of steel to the specific site conditions and load requirements. Consulting with engineers and reputable steel building manufacturers ensures you’re not only compliant with code but also leveraging the most up-to-date innovations in metallurgy for maximum longevity.

Protective Coatings: Shielding Against Corrosion

Corrosion is one of the most common threats to metal structures, particularly in humid, coastal, or industrial areas that are exposed to chemicals. Applying protective coatings—such as galvanization (zinc dipping) or epoxy-based industrial paints containing corrosion inhibitors—acts as an effective external barrier. It’s crucial to select coatings that align with the building’s environment. For example, marine-grade coatings are ideal for coastal regions, while polyurethane or powder coatings provide excellent resistance in urban settings with high pollution levels.

Scheduled reapplication and spot treatment after each inspection can significantly extend the lifespan of the structure, as even high-quality coatings wear thin over time and exposure. Ensure that all fasteners, welds, and joints are properly protected, as these areas are particularly vulnerable.

Load Management: Balancing the Burden

Effective load management ensures your metal structure operates well within its design capabilities. Overloading—whether from equipment, storage, snow accumulation, or temporary construction works—can cause frame distortion, cracks, or even catastrophic collapse. Routine reviews of intended and actual loads, coupled with periodic recalibration of use as building needs evolve, prevent hidden weaknesses from escalating.

Integrating balanced load distribution into the original design—by positioning support columns, trusses, and reinforcements effectively—is fundamental. Regularly confirm that all equipment or additions remain within engineered tolerances, and never undertake modifications or changes of use without professional assessment.

Drainage Systems: Preventing Water Damage

Moisture is a persistent adversary for any metal structure. An efficient drainage system, including gutters, downspouts, and water diverters, channels water safely away from the building’s foundation and structural supports. Standing water or leaks promote corrosion at joints and weaken the base, leading to long-term problems that are expensive to address.

Inspect and clear drainage systems regularly, especially in areas with heavy rainfall or dense foliage. Effective grading at ground level to slope water away from the structure further minimizes risk. Waterproof membranes, seals, and regular maintenance of roof systems offer additional layers of security against incursion.

Sustainability Practices: Building for the Future

Sustainable maintenance practices not only enhance lifespan but also contribute to energy efficiency and reduced environmental impact. Many metal structures benefit from recycled content, and almost all are ultimately recyclable at the end of their service life. Initiate recycling programs for leftover materials and use low-VOC paints, sealants, and refurbishment products.

Implementing energy-efficient upgrades—such as reflective coatings, insulated panels, and strategically placed windows for natural lighting—further reduces operational costs and the carbon footprint. Aligning your maintenance protocols with sustainability standards assures compliance with modern regulations while positioning your structure for long-term viability.

Conclusion

Building and maintaining strong metal structures hinges on a combination of quality materials, attentive design, and diligent, ongoing care. By prioritizing regular inspections, selecting the appropriate steel grades, applying protective coatings, managing loads prudently, maintaining effective drainage, and embracing sustainability, you can ensure the structural integrity and functionality of your metal investment for generations. Proactive strategies not only reduce risks and costs but also ensure your structures meet the demands of safety, performance, and environmental responsibility.