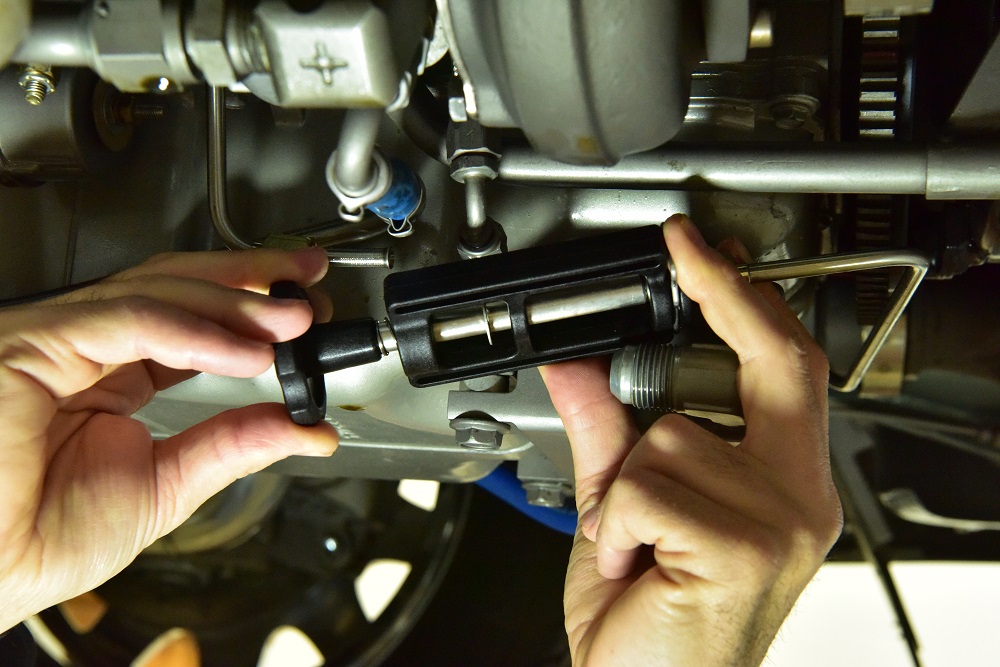

Troubleshooting Common Issues with Brake Line Flaring: Tips and Tricks

The brake lines are the parts of a car that prevent it from stopping when you need it to. Comparable to the unsung heroes of traffic safety, they carry out their duties in silence up until anything goes wrong. Brake lines are necessary to guarantee a strong connection and proper brake performance because of their flare. However, like with anything automotive, things don’t always go as planned.

Let’s now talk about some common issues that could occur with brake line fittings and flares and how to resolve them successfully.

Learning About Your Fittings and Flares

First, let’s discuss the many types of fits and flares that might occur. Inverted flares and bubble flares are the two primary varieties. The most prevalent kind of flares is inverted ones. This bends the end of the tube inward, creating a double flare. The tube end is bent outward in bubble flares, and there is just one flare on the other side. While each has a function, they might potentially provide a distinct set of difficulties throughout the flaring process.

Inverted flare fittings are a typical fitting used on most automobile braking systems. The conical seat in these fittings imitates the shape of the inverted flare on the tubing to provide a tight seal. Use the appropriate flare and fitting for your car’s braking system to ensure compatibility and dependability.

5 Typical Problems and Their Fixes

Material Compatibility

The Problem – Using gasoline line tubing or other unsuitable materials for brake lines might cause corrosion and failure.

How to Fix It – It is always advised to use brake line tubing and fittings since they are designed to withstand the high pressures and corrosive conditions seen in braking applications. Avoid using materials that can corrode over time, such as fuel line tubing, as they may not be suitable for brake fluid.

Cracked Flare

The Problem – The integrity of the seal may occasionally be jeopardized by cracks or splits in the flare.

How to Fix It – During the flare process, excessive force or incorrect technique is frequently the cause of this problem. The brake line flaring tool should not be over-tightened as this might distort and shatter the metal. To lessen friction during flaring, make sure the tube is well lubricated. It could be required to cut out the damaged flare part and flare the tubing if a flare does crack.

Incomplete Flare

The Problem – The flare may not always occur completely, leaving the tube end somewhat unflamed.

How to Fix It – Verify again that the flaring tool is correctly set for the desired flare size and that the tubing is firmly gripped within. To guarantee a full flare, operate the flaring tool with enough pressure. Adjust the tool and reflate the tube as needed to get the required form.

Incorrect Flare Type

The Problem – Compatibility problems and leaks might arise from using the incorrect kind of flare or fitting.

How to Fix It – To find the appropriate flare and fit for your braking system, go to the specs of your car or check a repair manual. Make sure that the fuel line tubing and tool are configured to generate the right kind of flare, either bubble or inverted. The performance of the brakes might be hampered by leaks caused by using the incorrect kind of flare.

Uneven Flare

The Problem – Occasionally, the flaring tool may produce an uneven flare, which might lead to an incorrect fitting seal.

How to Fix It – Before flaring, make sure the tubing is placed and aligned correctly in the flaring tool. To produce a uniform flare, operate the flaring tool with constant pressure. To get a more uniform shape, adjust the tubing and flare if needed.

Wrapping Up

More than just a technical chore, flaring brake lines is an essential step in maintaining the safe and efficient operation of your car’s brakes. Following the guide given here and being aware of the typical problems covered here will enable you to handle any flare hitches like an expert. Always equip yourself with the necessary equipment, supplies, and knowledge, and don’t hesitate to ask for professional assistance should you run into trouble. If you put in a little effort and show a little craftsmanship, your brake lines should work perfectly for many miles to come. People, please drive carefully!