Benefits of Using Flex PCBs in Your Electronic Designs

Without a printed circuit board, no electronic configuration inside a machine or gadget feels complete. And without a flex PCB, some electronic devices are not perfect, such as smartphones, laptops and wearable devices. Flex circuit board sees a lot of usage across different working fields, whether for industrial, medical, automotive, military, or aerospace purposes. Therefore, this kind of PCB tends to be quite in demand in the market, where plenty of organizations tend to place orders for these boards in bulk.

In this article, we’ll explore what a Flex circuit board is, and we’ll also explore the many benefits it can bring to your electronic designs.

What is a Flex PCB, and where does it see use?

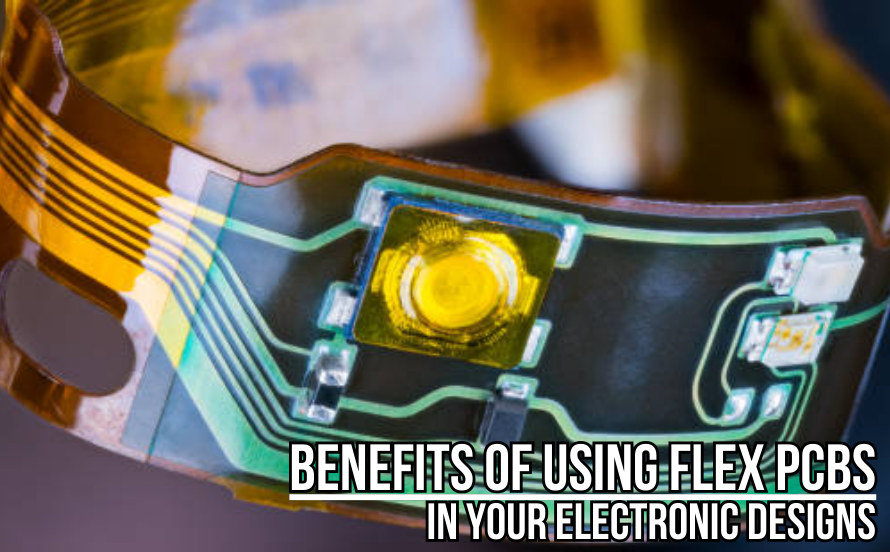

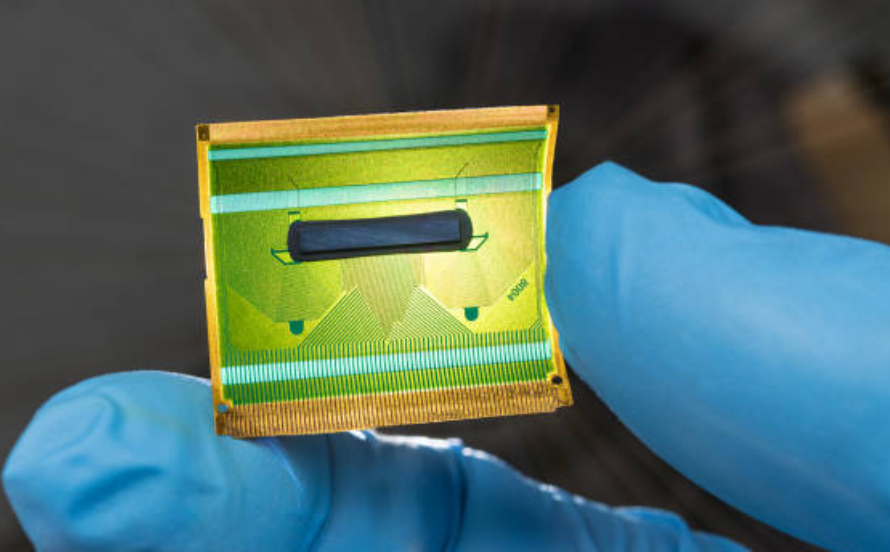

Before we proceed to the main topic, let’s understand what is a flex printed circuit board. A flex PCB is a type of circuit board that’s made out of bendable materials such as polyimide, making it more flexible and resistant to vibrations, unlike a rigid printed circuit board. Aside from their bendable properties, their other defining traits are their miniaturized designs and fewer connection points, which nullify defects caused by solder joint-induced interlinking defects.

A flexible printed circuit board consists of a dielectric substrate film, which is usually made out of polyimide, which is temperature- and traction-resistant, conductive materials such as copper, and a cover coat. An adhesive, such as epoxy, is used to keep these parts together.

In terms of usage, a flex PCB sees usage in items such as consumer products, military gear, aerospace tools and equipment, and specific medical equipment. Some examples where these boards are applied are tablets and cameras, AWACS, radio systems, defibrillators, and specific implants.

The perks of using a Flex PCB

A flexible printed circuit board offers a myriad of advantages to your electronic designs if used to their full potential. In this section, we’ll discuss all of its advantages and how they can elevate your organization’s gadgets and electronics.

1. Flexible and can reduce your gadget’s package requirements

The most notable advantage that a flex PCB can bring to your electronic designs is that it can give way to the miniaturization of your gadgets or equipment. In comparison to most standard connection solutions, flexible PCBs will occupy space that is roughly around a tenth of the space they occupy to ensure proper device function.

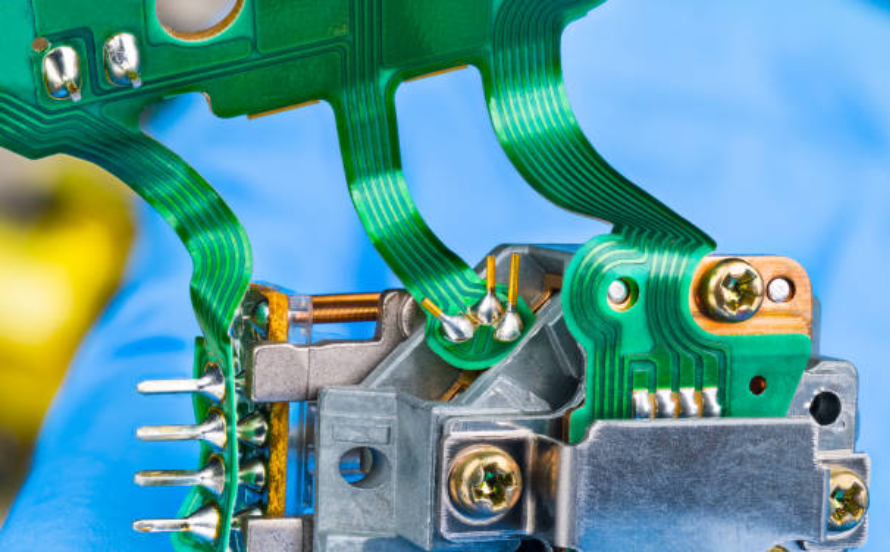

In addition to that, a flex PCB also offers the advantage of being bent, folded, or creased according to the user’s desired configuration. Aside from meeting the desired setup for the user, it also allows the strategic positioning of the circuit board even inside the smallest niches found inside the machine it will operate within.

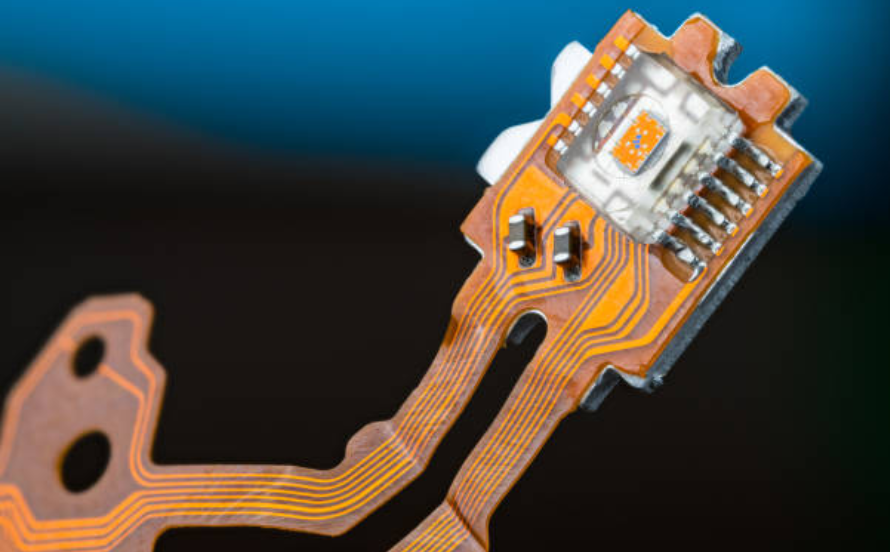

2. Eliminates the necessity of multiple connection solutions

Due to the flex PCB board’s easily bent or foldable nature, it also eliminates the necessity of multiple connections or linkages to the electronic design. Therefore, it will free up more space and also give way to the miniaturization of the circuit board’s size. In some cases, a flex circuit board is more than enough to replace different connector types within one integrated unit.

3. Reliable to use

Due to their reduced number of interconnects and linkages, a flex PCB is more than capable of fulfilling its function within an electronic design. As mentioned earlier, it gives way to lessening the need for multiple interconnects or convoluted linkages, which means there are fewer failure points within your electronic design. Therefore, it increases the reliability of your concept design as it can function better than those with complex linkages that are more likely to fail.

In addition, the flex circuits have a ductile property and aren’t too heavy, which makes them less prone to vibration or impact-based damage and heightens their performance levels.

4. Consistent signal performance

A flex PCB board is a nice investment for any organization that aims to make its devices and gadgets functional at a high level. That’s because these boards have very consistent and speedy signal performance. Due to their material’s consistent thinness, there’s little interference in the transmission of the electric signals to the linkages present in the circuit board.

Thus, devices that utilize a flex circuit board are more likely to be receptive to any input provided by the user.

5. Fares against environmental exposure are higher than standard PCB

If there’s a notable perk that a flex PCB board can do compared to a standard circuit board, it is its resistance against environmental exposure. Flex boards are far more impervious against moisture, oils, acids, and the like and aren’t easily deteriorated by them. On top of that, they are pretty resilient against ultraviolet rays and radiation.

Also, a flex circuit board can resist hot or cold temperatures averaging between a hundred degrees below freezing and around 200–300 degrees above the boiling point of water, and that’s due to their improved heat dissipation compared to standard PCBs. On top of that, flex boards are also very resistant to high voltage exposure, wherein they peak at 3000 volts.

6. Cost-efficient, saving you more money

Many organizations seek out a flex PCB manufacturer because printed circuit boards are cheaper once you consider all the factors playing into their costs. First off, the smaller circuit boards reduce the total costs of the materials used to manufacture them. The second is that there are fewer connectors or linkages, which also plays a role in the pricing of these flexible circuit boards.

Next, these boards are most likely to have been tested. Testing the product is proven to be an effective way to mitigate costs, as it allows the early detection of errors if any are present. Lastly, there are fewer component assembly requirements wherein the board is installed and can be set up in one cycle. All of the mentioned factors play up to why a flex PCB is cost-efficient and can help your organization save more.

7. Flexible connector compatibility

The last advantage of a flex PCB board that we’ll cover is its vast compatibility with many connectors if the need arises. It is capable of accepting linkages such as a high-density BGA, for instance. Also, the board itself can offer additional interconnect options, such as hot bar soldering.

Harnessing the Flex PCB’s benefits elevates your designs

By taking note of the many benefits that a flex PCB board can bring to your organization, you can take your electronic designs to the next level. By investing in quality flex circuit boards, you can be assured that your items will function as intended, and at the same time, you won’t have to spend additional money to get them fixed, as manufacturers have likely tested the boards for defects.

Once you’ve understood what we’ve discussed here, then it’s about time that you seek out a flex PCB manufacturer that could deliver on your expectations.