Advantages of Using Monel Metal in Marine Applications

Monel (a nickel-copper alloy) renowned for its exceptional corrosion resistance and high strength, has long been a preferred material for various marine applications. From shipbuilding to offshore structures, Monel offers numerous advantages that make it indispensable in harsh marine environments. This article explores the unique properties and benefits of Monel metal in marine applications, with a focus on Monel 400, one of the most widely used grades in the marine industry.

Corrosion Resistance

One of the primary advantages of Monel metal in marine applications is its outstanding corrosion resistance, particularly in seawater and marine atmospheres. Monel 400, composed of approximately 67% nickel and 30% copper, exhibits exceptional resistance to corrosion by seawater, brine, and various acidic and alkaline solutions encountered in marine environments. This resistance to corrosion helps prevent degradation and extends the service life of marine components, reducing maintenance costs and downtime.

High Strength and Toughness

Monel alloys( Monel 400), possess excellent mechanical properties, including high tensile strength, toughness, and ductility. These attributes make Monel metal well-suited for marine applications where strength and reliability are paramount. Monel components can withstand high-stress conditions— those experienced in ship hulls, propeller shafts, valves, and seawater piping systems, without succumbing to deformation or failure, ensuring the structural integrity and safety of marine vessels and infrastructure.

Resistance to Biofouling and Cavitation

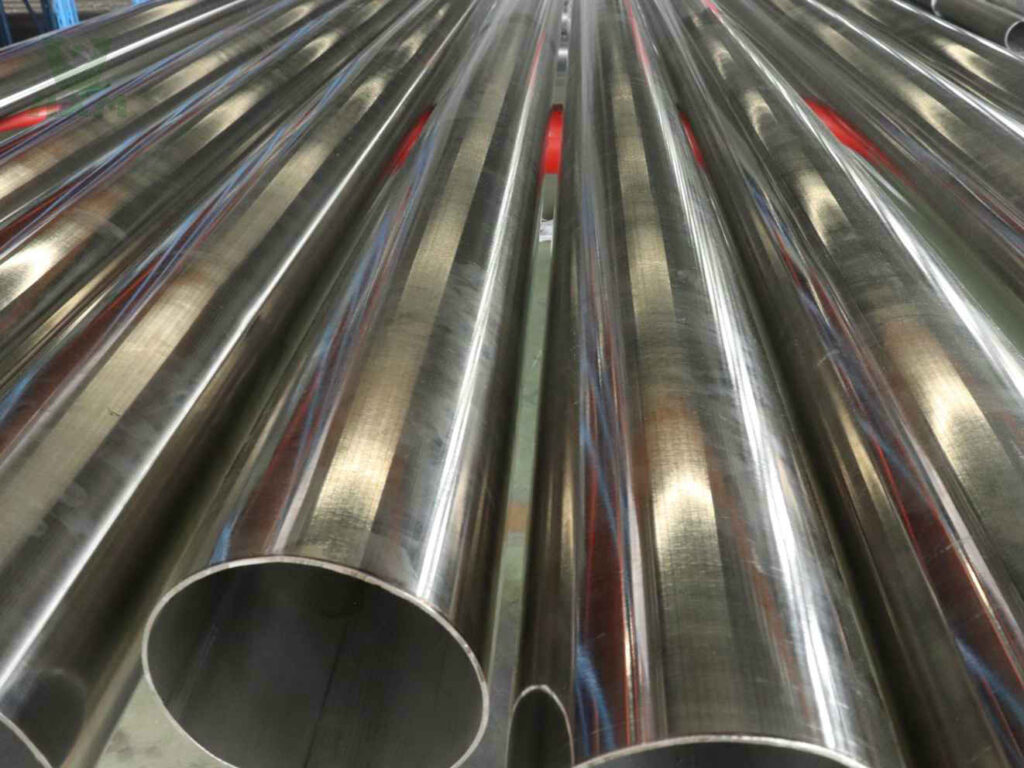

Biofouling, the accumulation of marine organisms ( barnacles and algae on submerged surfaces) can impair the performance and efficiency of marine equipment and structures. Monel’s smooth surface finish and resistance to biofouling make it a good choice for components exposed to seawater— ship hulls, propellers, and heat exchanger tubes. Additionally, Monel exhibits resistance to cavitation erosion, a phenomenon caused by the formation and collapse of vapor bubbles in high-velocity water flows, further enhancing its durability in marine applications.

Thermal Stability

Monel metal maintains its mechanical properties and corrosion resistance over a wide range of temperatures which making it suitable for marine applications subjected to fluctuating thermal conditions. Whether exposed to extreme cold in polar regions or high temperatures in tropical climates, Monel retains its integrity and performance, ensuring reliable operation and longevity of marine equipment and structures.

Weldability and Fabrication

Monel alloys( including Monel 400 ) are readily weldable and can be fabricated using common welding techniques, such as gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW). This weldability allows for the seamless integration of Monel components into complex marine structures, facilitating efficient construction and repair processes. Additionally, Monel can be easily formed, machined, and joined, offering flexibility in design and manufacturing of marine equipment and assemblies.

Conclusion

Monel metal, particularly Monel 400, offers a multitude of advantages that make it indispensable in marine applications. Its exceptional corrosion resistance, high strength and toughness, resistance to biofouling and cavitation, thermal stability, and weldability make it an ideal choice for a wide range of marine components and structures.

By leveraging the unique properties of Monel, marine engineers and designers can create robust, reliable, and long-lasting solutions that withstand the rigors of the marine environment, ensuring the safety, efficiency, and sustainability of marine operations.